Thank you for your interest in Nucor Lexington

We are excited to be building our new bar mill in Davidson County, North Carolina. This website is dedicated to maintaining open communication with our new community, career seekers and potential vendors and suppliers. Check back often for updates as this project progresses.

-

Subscribe to the Nucor Lexington Newsletter

Complete this online form to subscribe to the Nucor Lexington Newsletter. -

Read the full press release

Nucor to Build New Rebar Micro Mill in North Carolina

CHARLOTTE, N.C., April 7, 2022 Nucor Corporation (NYSE: NUE) announced today that it will build a new rebar micro mill in Lexington, North Carolina, which is located in Davidson County. This will be Nucor's third rebar micro mill, joining existing Nucor micro mills in Missouri and Florida. The Nucor Steel Lexington mill is expected to cost approximately $350 million and have an annual capacity of 430,000 tons. The mill will employ approximately 200 full-time teammates when operational and create an additional 500 temporary jobs during construction, which is expected to take two years pending permit and regulatory approvals.

"We are very excited to grow our steel business here in our home state of North Carolina. The corridor between Washington, D.C., and Atlanta is one of the fastest-growing regions in our nation, and new federal spending for infrastructure will further increase demand for rebar in the region," said Leon Topalian, President & Chief Executive Officer of Nucor. "Nucor Steel Lexington will produce steel with nearly 100% recycled content, which means our new, modern infrastructure will be made with the most sustainable steel available anywhere in the world."

Rebar is used primarily in concrete reinforcement for the construction of roads, buildings, bridges and other structures. Nucor produces steel by recycling scrap metal into new steel products, making the Company one of the most sustainable steel producers in the world. Nucor steel bar products contain 97% recycled content.

"We would like to thank Governor Roy Cooper, Commerce Secretary Machelle Baker Sanders and other state officials, Davidson County, the City of Lexington and the City of Thomasville for their help and support of this project. We are excited to grow our Nucor family in this area and to partner with local schools and non-profit organizations that support members of this community," said Mike Hess, Vice President & General Manager of Nucor Steel Lexington.

Nucor has 15 bar mills strategically located across the United States that manufacture a broad range of steel products, including concrete reinforcing bars, hot-rolled bars, rounds, light shapes, structural angles, channels, wire rod and highway products in carbon and alloy steels. Four of the bar mills have a significant focus on manufacturing SBQ and wire rod products. Steel produced by Nucor bar mills serves numerous end-use markets, including the agricultural, automotive, construction, energy, furniture, machinery, metal building, railroad, recreational equipment, shipbuilding, heavy truck and trailer market segments. Nucor's steel bar production capacity is estimated at approximately 9,560,000 tons per year.

Nucor has operated its corporate headquarters in Charlotte, North Carolina since 1966. The Company directly and through affiliates employs approximately 800 teammates in the state, including a steel plate mill in Hertford County, a Harris Rebar fabrication facility in Lumberton and three scrap recycling facilities, which will provide raw materials for the new mill.

About Nucor

Nucor and its affiliates are manufacturers of steel and steel products, with operating facilities in the United States, Canada and Mexico. Products produced include: carbon and alloy steel -- in bars, beams, sheet and plate; hollow structural section tubing; electrical conduit; steel racking; steel piling; steel joists and joist girders; steel deck; fabricated concrete reinforcing steel; cold finished steel; precision castings; steel fasteners; metal building systems; insulated metal panels; steel grating; and wire and wire mesh. Nucor, through The David J. Joseph Company, also brokers ferrous and nonferrous metals, pig iron and hot briquetted iron / direct reduced iron; supplies ferro-alloys; and processes ferrous and nonferrous scrap. Nucor is North America's largest recycler.

Forward-Looking Statements

Certain statements contained in this news release are "forward-looking statements" that involve risks and uncertainties. The words "anticipate," "believe," "expect," "intend," "project," "may," "will," "should," "could" and similar expressions are intended to identify those forward-looking statements. These forward-looking statements reflect the Company's best judgment based on current information, and, although we base these statements on circumstances that we believe to be reasonable when made, there can be no assurance that future events will not affect the accuracy of such forward-looking information. As such, the forward-looking statements are not guarantees of future performance, and actual results may vary materially from the projected results and expectations discussed in this news release. Factors that might cause the Company's actual results to differ materially from those anticipated in forward-looking statements include, but are not limited to: (1) competitive pressure on sales and pricing, including pressure from imports and substitute materials; (2) U.S. and foreign trade policies affecting steel imports or exports; (3) the sensitivity of the results of our operations to prevailing market steel prices and changes in the supply and cost of raw materials, including pig iron, iron ore and scrap steel; (4) the availability and cost of electricity and natural gas, which could negatively affect our cost of steel production or result in a delay or cancellation of existing or future drilling within our natural gas drilling programs; (5) critical equipment failures and business interruptions; (6) market demand for steel products, which, in the case of many of our products, is driven by the level of nonresidential construction activity in the United States; (7) impairment in the recorded value of inventory, equity investments, fixed assets, goodwill or other long-lived assets; (8) uncertainties surrounding the global economy, including excess world capacity for steel production; (9) fluctuations in currency conversion rates; (10) significant changes in laws or government regulations affecting environmental compliance, including legislation and regulations that result in greater regulation of greenhouse gas emissions that could increase our energy costs, capital expenditures and operating costs or cause one or more of our permits to be revoked or make it more difficult to obtain permit modifications; (11) the cyclical nature of the steel industry; (12) capital investments and their impact on our performance; (13) our safety performance; and (14) the impact of the COVID-19 pandemic and any variants of the virus. These and other factors are discussed in Nucor's regulatory filings with the Securities and Exchange Commission, including those in "Item 1A. Risk Factors" of Nucor's Annual Report on Form 10-K for the year ended December 31, 2020. The forward-looking statements contained in this news release speak only as of this date, and Nucor does not assume any obligation to update them, except as may be required by applicable law.

-

Learn More About The Mill

-

Are you interested in becoming a Nucor Teammate?

Nucor teammates feel a sense of pride for our company, thanks to the stability, family-like culture, and freedom to make decisions that the Nucor work environment is known for. Nucor represents a place where everyone is looking out for each other while doing their part to make Nucor safer, more efficient, and more productive while forging life-long friendships and career opportunities along the way. We are looking for candidates who are highly motivated and inquisitive individuals, who take initiative in their work, and strive for continuous improvement to join the Nucor family.

As we embark on the next steps of establishing our new micro mill, we will provide updates to timeline and hiring process here as new details develop. In the meantime, please join our Talent Network by entering your email address to create a candidate profile.

Once you are a part of our Talent Network, you can create an alert to be made aware of any Lexington jobs made available.

Join Talent NetworkWant to be a Nucor Teammate now?

Nucor has job opportunities available throughout the country.

Search Job Opportunities -

Interested in becoming a supplier or vendor?

Thank you for your interest in Nucor Steel Lexington! To the extent possible, we will provide information for suppliers and vendors as opportunities arise. Continue to check back on this site for updates as the project progresses.

-

Photo Gallery

Nucor Steel Lexington Vice President & General Manager, Mike Hess, speaks to attendees at the announcement.

NC Department of Commerce Secretary Machelle Baker Sanders gives a commemorative North Carolina made piece of pottery to Leon Topalian, Nucor President and CEO.

Ben Pickett, Lexington Native and Nucor General Manager of Public Affairs & Counsel, speaks to attendees at the announcement.

Leon Topalian gives a $50,000 check to the Holly Grove Fire Department

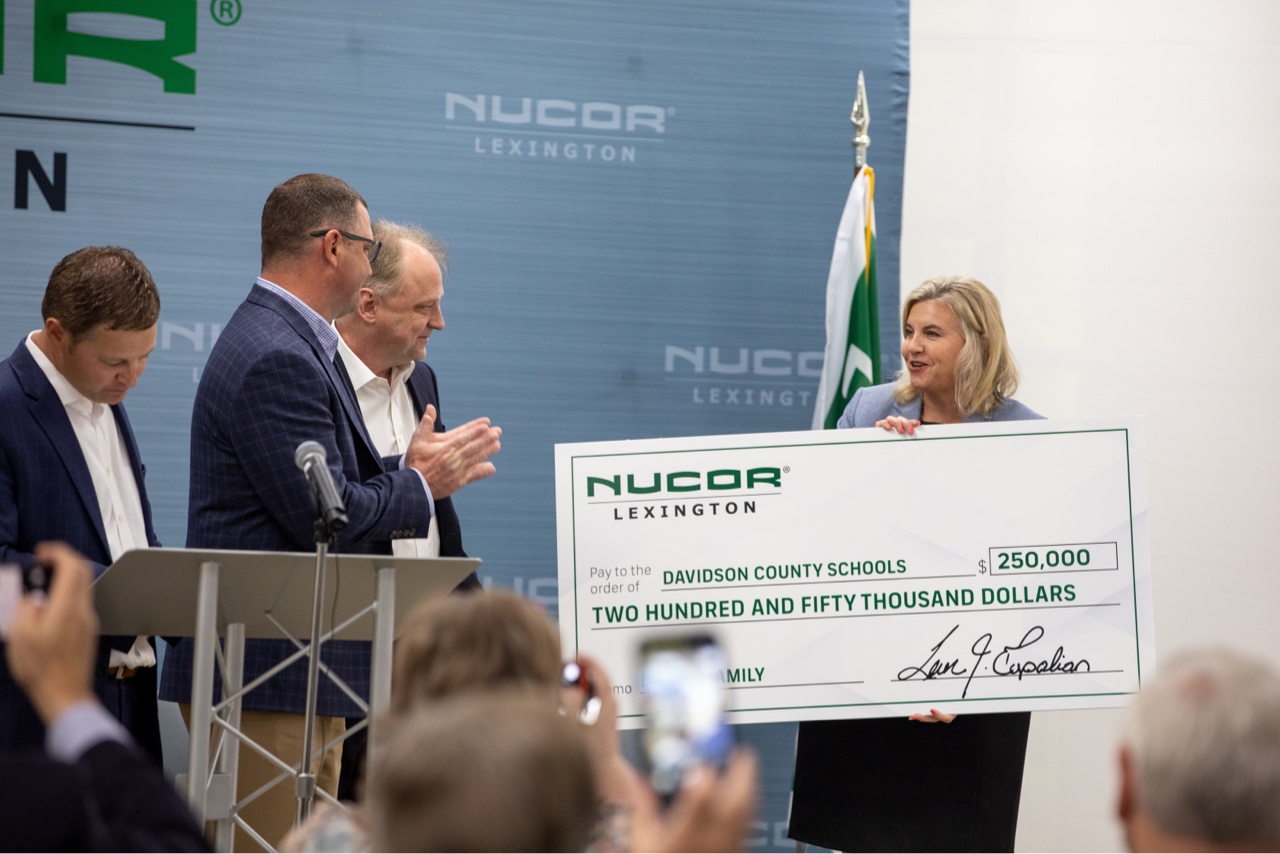

Representatives from the City of Lexington Schools receive a $250,000 check from Nucor.

Representatives from the City of Thomasville receive a $250,000 check from Nucor.

A representative from Davidson County Schools receives a $250,000 check from Nucor.